Optimize Efficiency

Optimize Efficiency

Help your customers achieve their sustainability goals and reduce their energy and lifecycle costs

Innovation

Innovation

Develop smart, connected equipment that generates actionable data

Accelerate Your Revenue

Accelerate Your Revenue

Introduce sustainable solutions faster and unlock new aftermarket revenue streams

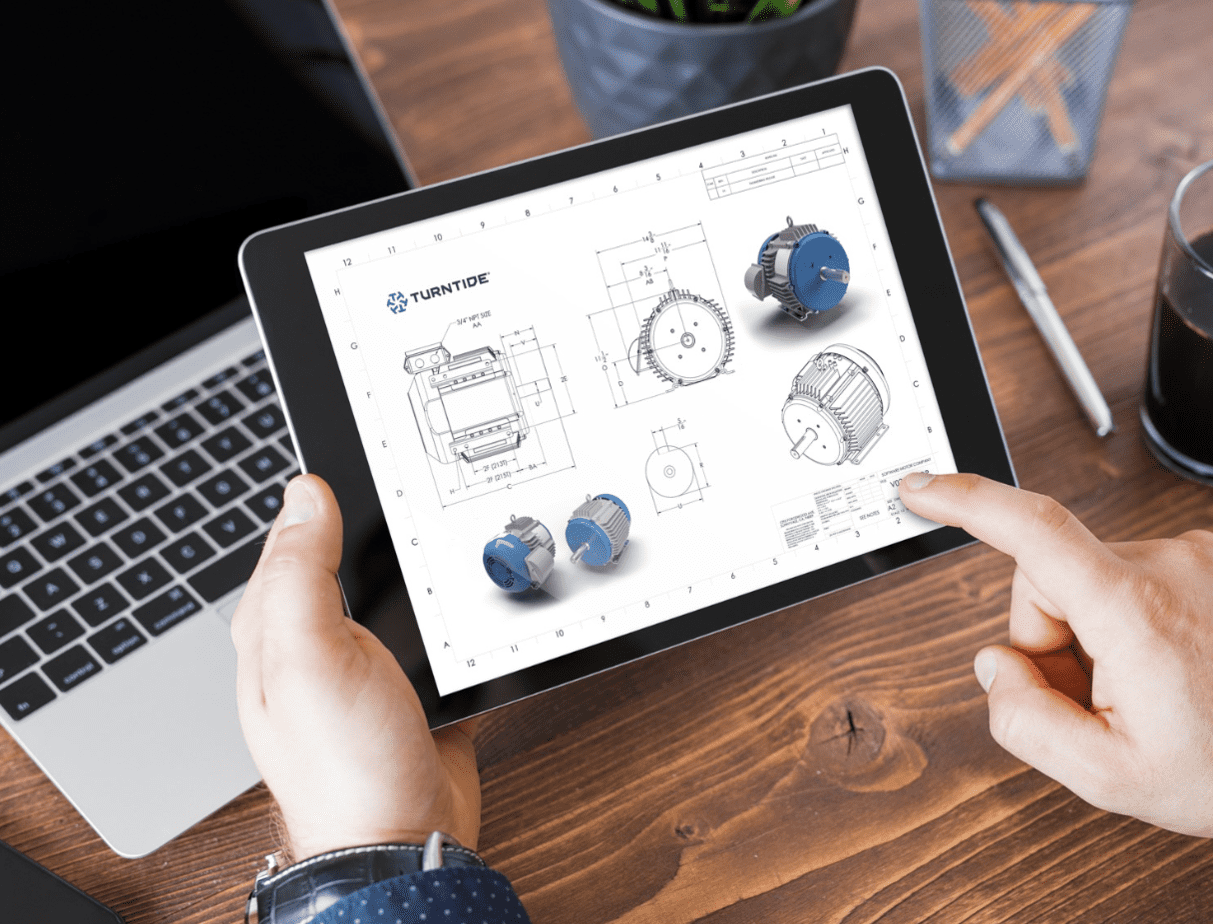

Introducing the Smart Motor System™

Reduces energy usage by an average of 64%

Our patented Optimal Efficiency Motors™ assure peak energy efficiency and reliability through superior design physics, enhancing the value of your solutions.

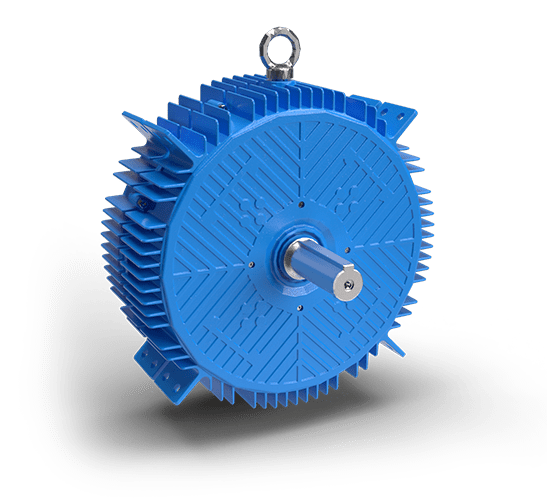

Smart Motor System - TX Series

This slim profile motor is ideal for use in fan arrays in mission-critical cooling systems

- Optimal efficiency through superior device physics

- Ultra-reliable performance across all speeds

- Slim design to minimize motor footprint

- Reduced bearing failure

- Reduced weight

- 93.2% peak motor efficiency

- Smart Motor diagnostics

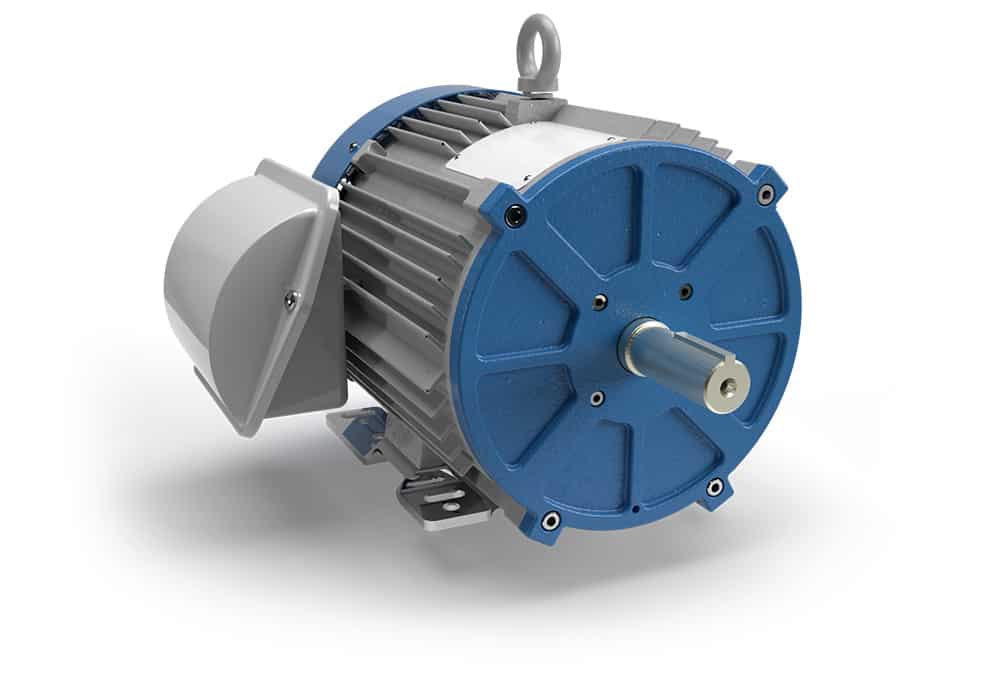

Smart Motor System - V Series

This high-efficiency motor is well suited for use in HVAC RTUs and pumps

- High rotor pole switched-reluctance motor

- Reliable

- Exceeds IE5 across most HP

- Standard NEMA frames

- Standard IEC frames

- Lubed-for-life bearings

IOT capabilities enabled through the Smart Motor System

-

- Multi-site visibility

- Virtual motor commissioning

- Remote firmware updates

- Measurement and verification

- Energy use reduction

- No permanent magnets, no rare earth minerals

- Rebate qualification

-

- Fully IOT enabled equipment with digital twin

- Monitoring, fault detection and diagnostics

- Notifications and alerts

- Optimized maintenance schedules

- Enables Equipment-as-a-Service

- Simplified specifications, fewer SKUs

-

- Work order management system integration

- Customized dashboards and reports

- Analytics to improve performance and design

-

- Multi-site visibility

- Virtual motor commissioning

- Remote firmware updates

- Measurement and verification

- Energy use reduction

- No permanent magnets, no rare earth minerals

- Rebate qualification

-

- Fully IOT enabled equipment with digital twin

- Monitoring, fault detection and diagnostics

- Notifications and alerts

- Optimized maintenance schedules

- Enables Equipment-as-a-Service

- Simplified specifications, fewer SKUs

-

- Work order management system integration

- Customized dashboards and reports

- Analytics to improve performance and design

Solutions for a range of industries and applications

Smart HVAC for Data Centers

Smart HVAC helps data centers optimize temperature control and cooling systems to ensure mission-critical facilities stay online without interruption and meet PUE targets and net zero goals.

Mission-Critical Cooling Systems for Labs

Smart Cooling Systems help labs maintain temperature consistency and adequate ventilation so that the integrity of samples and the health of workers are not compromised and expenses are kept under control.

General Purpose HVAC

HVAC systems monitor and gather vast amounts of data related to energy consumption and peak usage time daily. Operators and facility managers can use this data to derive insights and, coupled with building automation systems (BASs), lead to better energy and resource management.

Energy-Efficient Pumps

Continuous monitoring of pump performance is imperative to identify and prevent energy losses occurring during the production process. Embedding intelligent sensors, real-time monitoring tools, and software helps end users gain visibility into pump performance and improve pump efficiency and life.

Benefits to OEMs and their customers

Take the next step

Talk to our team to see how we can work together to bring sustainable solutions to market faster.

Schedule a consult