Accelerate the Path to Electrification

Decreasing emissions and meeting the stringent regulations in the U.S. from the Environmental Protection Agency, the U.K. from the Health Security Agency, and the E.U. from the Agency for the Cooperation of Energy Regulators. However, the world will not convert to zero emissions overnight. Currently, several alternative power options make up the equation for decreasing carbon emissions. These include:

- Biodiesel and other lower carbon biofuels

- Electrification

- Hydrogen (fuel cell and combustion engines)

At this moment, electrification leads the way because it is already widely used in passenger vehicles and smaller construction and agricultural equipment. In addition, the charging infrastructure is much more mature than biodiesel’s or hydrogen’s infrastructure. How do you get started on the path to electrification?

The Path to Electrification Calls for the

Right Technology

The components required for electrification are motors, power electronics, thermal solutions (pumps and fans), and energy storage. These components allow manufacturers to travel the electrification path safely and faster with less risk and higher performance.

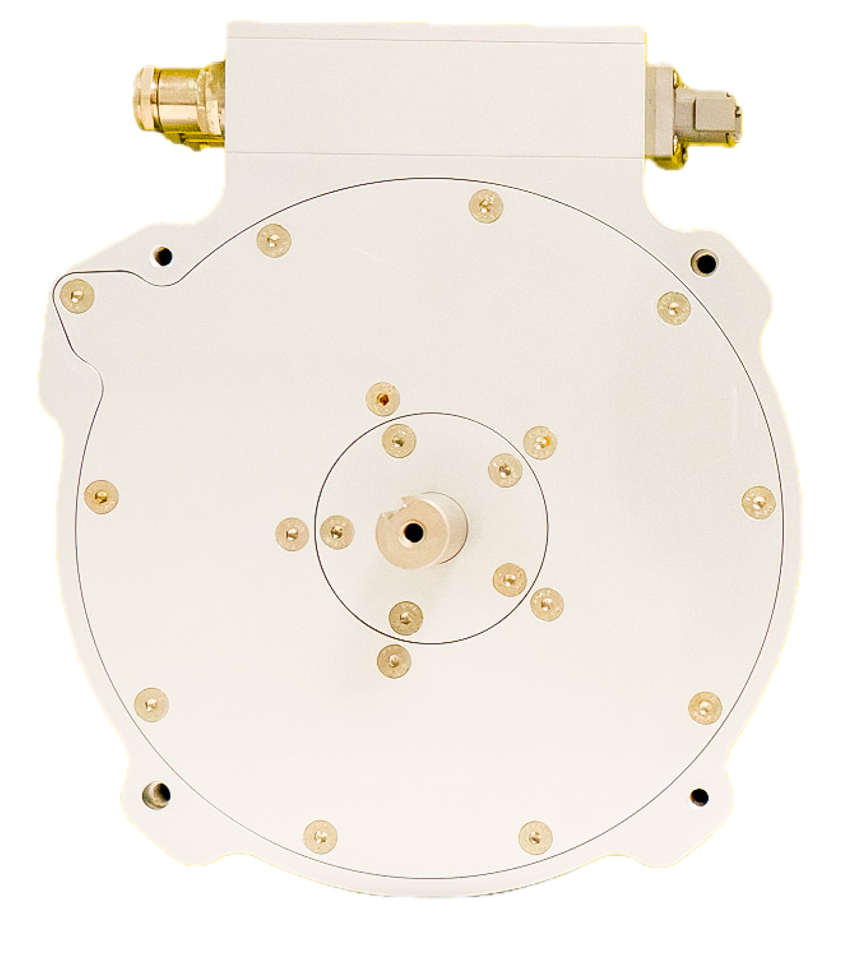

Axial Flux Motors

Axial flux motors, often called pancake motors, are flatter. In space-constrained, electric vehicles and equipment, these flatter motors are ideal. They give engineers and designers more room for the battery and thermal solutions. Stackable, compact electric motors are designed for high power and torque density. Axial flux motors are perfectly suited for hybrid and retrofit applications, featuring liquid cooling using water/ethylene glycol for enhanced performance.

A key determinant of torque and power delivery and, therefore, efficiency of the electric motor is the magnetic field strength. Magnetic field strength will be higher if the magnetic flux path is shorter.

Therefore, field strength increases with diameter (D) of the rotor containing the magnetic material and reduces with the length (L) of the flux path. A higher D/L ratio provides a motor with a higher efficiency and a higher torque density.

Power Electronics

Power electronics include high-voltage inverters, low-voltage motor controllers, and DC/DC converters. They are other requirements for electrification. They are designed for traction, generation, and auxiliary functions like pumps and fans.

Low-voltage inverters are ideal for electrification applications in a wide array of industries’ smaller vehicles and equipment. These include all-terrain vehicles, three-wheel vehicles, motorcycles, go-karts, snowmobiles, and personal watercraft.

Larger vehicles and equipment often need a high-voltage inverter or motor controller. These include: excavators, loaders, dump trucks, underground mining vehicles, tractors, combine harvesters, military vehicles, trucks, buses, municipal vehicles, forklifts, aerial work platforms, and passenger and freight rail.

Thermal Solutions

To keep a high-energy, electric system cool and operating effectively and efficiently, a reliable cooling system is necessary. This means selecting the ideal fan and pump to match the heat developed by the system.

Some pumps boast an impressive lifespan of more than 40,000 hours. A pump with high-efficiency operation ensures optimal performance, coupled with a sealless centrifugal impeller design provides high-flow capabilities. Selecting a pump that is compliant with ISO 16750 Environmental test standards and offers CAN input or pulse width modulation input (for limited functionality).

The ideal fan for an electric or hybrid system is one with a brushless, sensorless motor for extended life that is environmentally sealed with IP67 protection. Full reversibility, advanced motor control, and integrated safeguards like thermal overload and voltage transient protection, are also recommended. Added CAN controllability and diagnostics can elevate the fans to the forefront of efficient and intelligent cooling technology.

Energy Storage

Lithium-ion modular battery solutions are the primary source for energy storage in electric and hybrid vehicles and equipment. Effective battery systems combine high-performance battery packs with system controllers for temperature and voltage measurement and internal cell balancing. These allow for flexible and scalable energy storage. The battery packs should be a rugged design ideal for many on- and off-highway applications from construction and agriculture to marine and material handling to commercial and municipal vehicles. Battery packs allow customers a flexible and scalable approach to meet any energy storage solution.

and voltage measurement and internal cell balancing.

Selecting the Best Supplier for Your Path

to Electrification

Working with a supplier that can help you go to market faster with a safe, tested vehicle or piece of equipment optimized for performance is the goal. How do you find the ideal provider? As you consider your partner, ask the following questions:

- Has the supplier worked on similar applications in your industry, and do they understand the compliance and safety issues?

- Does your supplier consistently produce high-quality products?

- Does your supplier spot risks and communicate issues before they arise?

- Does your supplier consistently invest in R&D and continuous improvement?

The supplier you choose must have experience and expertise in your industry vertical. The company must also provide quality products and have accountability during the project. If issues arise, they should proactively manage them and get your input early in the process with good communication, transparency, and trust. Ultimately, you want a partner with that values innovation, flexibility, and continuous improvement.

Ideally, the partner for your path to electrification will design, engineer, and manufacture their components. If they manage the entire process, their team is better able to ensure the quality of the components and work with you to provide the best component for your application. This includes designing full electrification solutions for early-stage proof-of-concept, prototypes, and retrofits, to manufacturing in mature markets with high-volume production demands.

Editor’s Note: Check out this e-book if you’d like a brand-specific version of this article.