Axial Flux Motors Electrify Auxiliary Functions in a Fuel-Cell Mining Truck

A manufacturer of decarbonization solutions for heavy industries needed to convert a rigid dump truck used in mining to operate with a hydrogen fuel-cell system. The truck had a 291-tonne payload. The system would include electric motors to drive important auxiliary functions, including two hydraulic pumps.

This project needed to retrofit traditional diesel-powered components with an electric powertrain while maintaining the truck’s performance, reliability, and efficiency in demanding mining environments.

Technical Challenge

The transition from a diesel-based to an electric-based powertrain creates a gap for the auxiliary hydraulic systems, which are no longer coupled to an engine for power. The motor characteristics required to support this transition were:

- High power and torque density – Ensuring efficient operation of auxiliary functions under extreme mining conditions.

- Scalability and customization – Motors had to be compact yet powerful enough to fit within strict space limitations.

- Sustained reliability – Designed to withstand harsh environmental conditions, including dust, vibrations, and extreme temperatures.

The Solution for Axial Flux Motors Electrify Auxiliary Functions

The project was split into two stages. The hydraulic system, comprised of two pumps driving steering, brakes, hoist, and the brake cooling system, was the first system to be electrified.

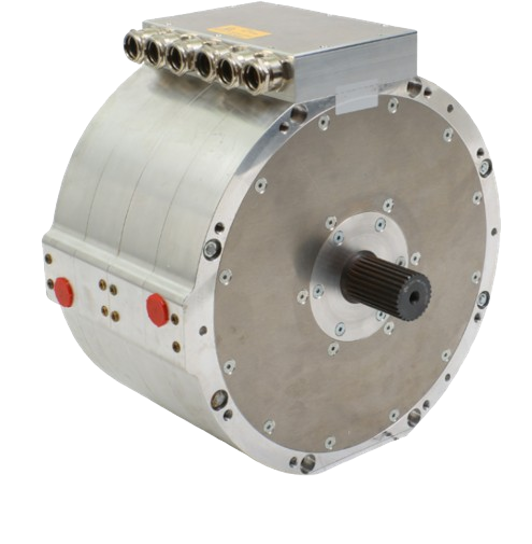

The axial flux motor manufacturer delivered a high-efficiency motor solution, two were required, one for each hydraulic pump. These motors optimized the auxiliary power management through:

- Scalable and customizable design – Compact yet powerful motor architecture tailored for space-constrained, heavy-duty mining applications.

- High torque and power density – Enabling efficient energy conversion while reducing system weight and improving vehicle efficiency.

The specifications of the motors are:

- Maximum speed – 5,000 (rpm)

- Continuous torque – 520 Newton meters (Nm)

- Peak torque at 20 seconds (s) – 1,200 Nm

- Nominal output power – 188 kilowatts (kW)

- Peak output power at 20 s – 440 kW

Performance Outcomes

By integrating axial flux motor technology, the decarbonization solution manufacturer successfully transitioned the rigid dump truck, replacing the combustion-driven auxiliaries with electric alternatives for a zero-emission solution.

The axial flux motors optimized energy efficiency, achieving superior thermal and power management, giving the manufacturer the ability to create an agnostic platform that supports reduced operational costs while minimizing environmental impact and is suitable for bespoke battery, fuel cell and hybrid technologies.

The transition also enabled future electrification scalability. This pioneering modular approach to fuel cell integration supports the mining industry’s shift toward sustainable, heavy-duty electrification. This project highlights how axial flux motors electrify auxiliary functions. It also shows axial flux motors’ role in advancing zero-emission mining technology, demonstrating the potential of high-efficiency electric powertrain solutions in extreme-duty applications.