Why Axial Flux Motors?

When selecting a motor for battery-electric vehicles or equipment, engineers typically choose between a radial flux motor or axial flux motor. They will need to select a motor that:

- Provides the torque and power needed

- Functions well within the system

- Fits in the available space in the vehicle or equipment

When working with weight-sensitive applications, the motor must also not be too heavy. In many cases, engineers and designers must choose between a radial flux motor and an axial flux motor.

Mechanical & Design Differences

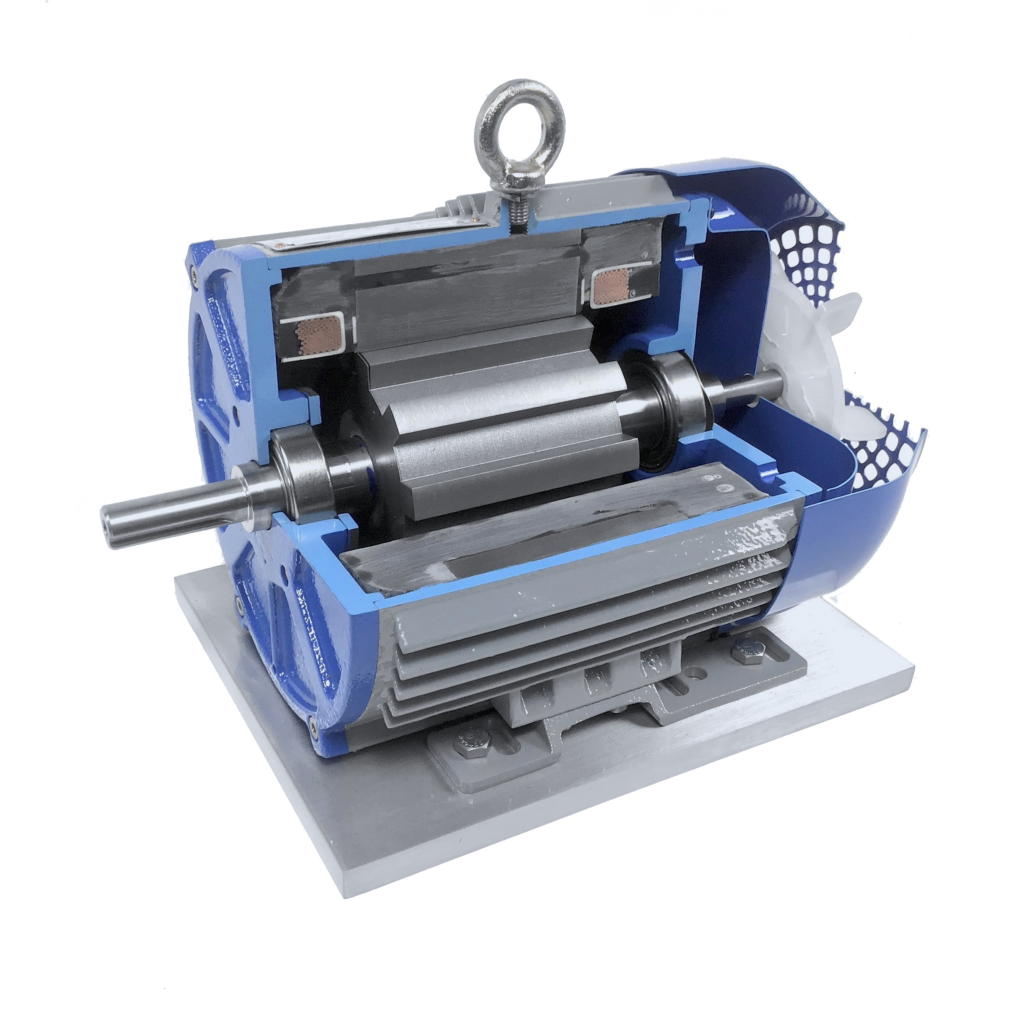

Radial flux motors are widely used and the motors that most think of when hearing about electric motors. They are used in many applications, including electric and hybrid vehicles (see Image 1). These motors have a long body and are heavy.

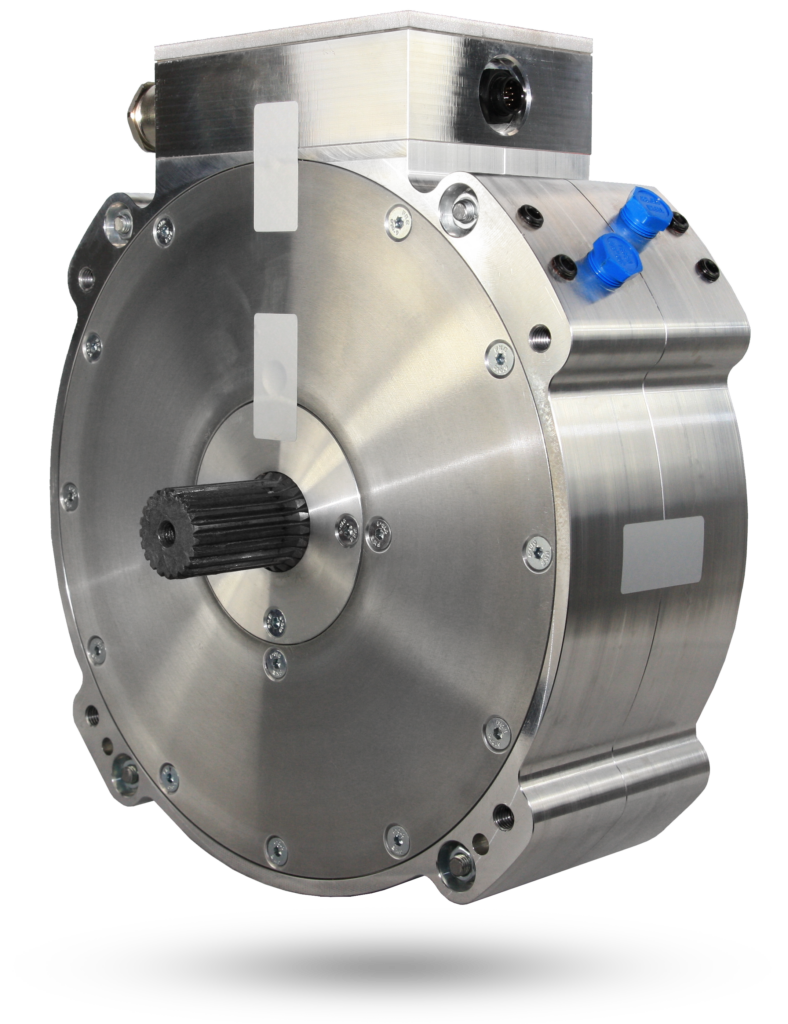

Axial flux motors may be an ideal choice is because they are flatter than a radial flux motor (see Image 2). Often called pancake motors, axial flux motors require less room and are ideal in space-constrained applications like electric or hybrid vehicles and equipment. They give engineers and designers more room for the battery, inverter or controller, and thermal solutions.

Axial flux motors are stackable, compact electric motors designed for high power and torque density. They are well-suited for hybrid and retrofit applications.

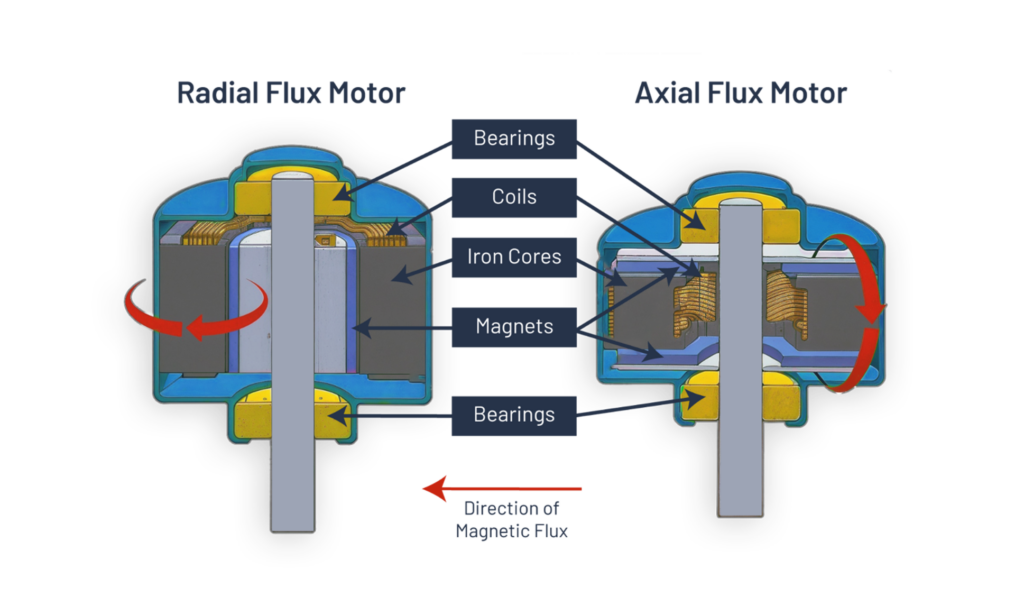

In addition, the windings of a radial flux motor are perpendicular to the magnets. In axial flux motors, the magnets are in planes parallel to the windings. This difference in the magnets and coils impacts the torque, power, and efficiency of the motors.

Comparison of Power & Torque Capabilities

Other reasons that axial flux motors are a great choice are torque, power, and efficiency. While they are lighter and require less space, their torque, power and efficiency are often higher than a radial flux motor. A key determinant of torque and power delivery and, therefore, efficiency is the magnetic field strength. Magnetic field strength will be higher if the magnetic flux path is shorter.

Therefore, field strength increases with the diameter (D) of the rotor containing the magnetic material and reduces with the length (L) of the flux path (see Image 3). A higher D/L ratio provides a motor with a higher efficiency and a higher torque density. Axial flux motors have a higher D/L ratio than radial flux motors. This gives them higher torque and power.

Depending on the motor’s size, axial flux motors are two to four times more torque dense than the standard radial flux motor. This torque improvement results in a 50% weight and volume savings for the powertrain. In addition, for a radial flux motor, the torque is proportional to the square of the diameter multiplied by the length. For an axial flux motor, the torque is proportional to the cube of the diameter, and it has no significant influence on the length. These factors explain the reason that they have more torque than a radial flux motor. This torque, less weight, and the flatter profile make them ideal for hybrid configurations or the fully electric system of any vehicles or equipment, especially if space is limited.

In addition, the weight difference matters. With axial flux weighing less, the vehicle’s range may increase. A 10% reduction in vehicle weight can improve the vehicle range by 13.7%.

Applications

While axial flux motors can be used in many systems, they are an excellent choice for hybrid and electric vehicles and equipment, where weight limits are present and space is at a premium. This includes:

- Premium automotive

- Traction for premium automotive cars and high-performance e-motorbikes

- On-highway

- Traction (including e-axle Integration)

- e-power take-off

- Ancillary applications such as cooling pumps and fans for battery-electric and hybrid-configuration vehicles

- Fuel cell superchargers

- Off-highway

- Construction and mining equipment (excavators, wheel loaders)—Wheel traction, track traction, and ancillary functions such as slew and swing

- Agriculture equipment—Wheel traction, track traction, and ancillary functions such as slew and swing

- Street sweepers—Traction and sweeping implements

- All-terrain vehicles—Traction

- Marine

- Offboard Motors and Marine e-Propellers

- Auxiliary power on hybrid boats—sailing, pleasure and fishing boats

- Winches and cranes on ships

- Rail

- Traction for trams and light railway

Why Axial Flux Motors?

So, why should engineers and designers of hybrid and electric vehicles and equipment select an axial flux motor? A recent report from IDTechEx indicated them as an emerging trend for electric machines.

According to the report, “The benefits of axial flux motors include increased power and torque density and a pancake form factor ideal for integration in various scenarios.”

If engineers and designers want to ensure an efficient, powerful system with light weight and a small footprint, then axial flux motors are the only choice.