Driving Cleaner Urban Mobility: A Case Study in Bus & Truck Electrification

A leading European original equipment manufacturer (OEM) wanted to move to bus and truck electrification to lower emissions and operating costs across its city bus and medium-duty truck lines. The OEM decided to partnering with an advanced electrification specialist to improve the emissions and efficiency of these vehicles.

Technical Challenge

Urban transit authorities are pressured to meet tightening air-quality targets while maintaining service schedules and controlling total cost of ownership. The OEM’s legacy diesel fleet faced three specific hurdles:

- Idle-related emissions – Frequent stop-and-go duty cycles created prolonged idling, wasting fuel and accelerating component wear.

- Parasitic energy losses – Conventional, mechanically driven pumps sapped engine power, decreasing the vehicle’s efficiency.

- Platform complexity – Deploying different subsystems for multiple vehicle variants inflated part counts, inventory costs, and certification timelines.

The OEM needed a robust, scalable approach that would:

- Deliver measurable emission reductions without overhauling the entire powertrain

- Meet International Organization for Standardization (ISO) 26262 functional-safety requirements

- Operate seamlessly across diesel, hybrid, and fully electric configurations

Technology Solution

Working as a Tier 1 electrification partner, the technology provider co-developed two complementary subsystems.

A 48-volt sensorless inverter helped solve the following challenges:

- Start/stop optimization – By pairing a sensor-less, switch-reluctance motor (SRM) with proprietary inverter controls, the bus can shut down and re-ignite its engine in less than a second at every stop.

- Functional safety, Automotive Safety Integrity Level B – The software was tailored to the OEM’s existing communication protocols while preserving ISO 26262 compliance.

- Cross-platform flexibility – The inverter’s modular control stack supports different motor sizes and mounting envelopes, allowing for rapid deployment in buses and trucks.

A 24-volt sealless cooling pump helped add the following benefits:

- Hydraulic performance – Capable of 2.1 bar maximum pressure and 100 liters per minute of flow, the pump manages thermal loads for batteries, inverters, and combustion engines.

- Efficiency gains – An electronically commutated motor eliminates belt-drive drag, cutting parasitic losses and decreasing fuel consumption.

- Durability road map – With a validated service life exceeding 40,000 hours and a development plan targeting near-silent operation, the pump aligns with fleet-wide noise-abatement goals.

- Common-platform design – One part number now supports diesel, hybrid-electric, and battery-electric variants, simplifying production logistics.

The pump’s specifications were:

- Best efficiency point at 1.85 bar static pressure rise – 72 liters per minute

- Rated voltage – 16 volts (V) to 32 V

- Max current – 19 amps

- Input DC power – 532 Watts

- Weight – 3.02 kilograms

- Minimum operating temp – -30°C

- Maximum operating temp – +75°C

Results

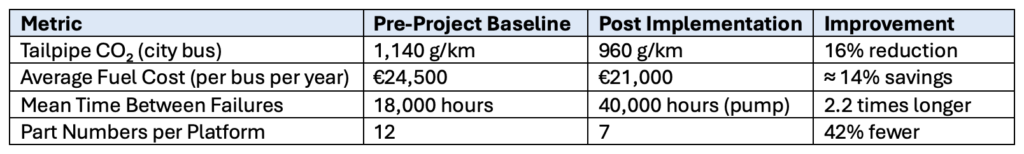

Partnering with an advanced electrification technology specialist, the OEM introduced two key subsystems—a 48-volt sensor-less inverter for diesel buses and a 24-volt (V) seal-less cooling pump for hybrid and battery-electric trucks and buses to move to bus and truck electrification. In series production since 2021, the integrated solution has decreased tailpipe emissions on select bus routes by 16%, reduced parasitic loads, and unlocked a reliable, common-platform architecture for future vehicle programs.

Operational data gathered during three years confirm that the inverter’s rapid start/stop strategy eliminated unnecessary idling while maintaining driver comfort, and the electronic pump lowers thermal-management energy draw by up to 500 watts per vehicle. Fleet managers also reported reduced maintenance downtime thanks to the pump’s seal-less architecture and longer service intervals.

Lessons Learned

The teams gained some valuable insights from this project:

- Sensor-less control accelerates ROI – Avoiding rotor position sensors reduced bill-of-material costs and simplified installation, helping the inverter pay for itself in less than two years.

- Holistic subsystem pairing matters – Tackling both electrical propulsion and thermal management delivered extra benefits in fuel economy, emissions, and reliability.

- Software customization is critical – Adapting the firmware to the OEM’s network protocols minimized requalification efforts and shortened the path to series production.

Future Outlook

Building on early success, the partners are evaluating:

- High-voltage, low-power (HVLP) inverter variants – Targeted at next-generation 600-volt architectures for articulated buses and regional trucks

- Second-generation cooling pump – Featuring advanced acoustic-damping and smart diagnostics to push toward zero-noise, predictive maintenance

- Full driveline electrification – Using the same control philosophy to integrate traction motors, DC-DC converters, and battery packs into a cohesive, modular suite

By combining modular hardware with application-specific software, the collaboration demonstrated a reproducible blueprint for fleet decarbonization—delivering quantifiable environmental gains today while laying the groundwork for tomorrow’s zero-emission vehicles.