Podcast Spotlight: Axial Flux Advances & Electrification Insights

The fast-moving world of electric and hybrid powertrains got two fresh injections of expert knowledge this month. Electronic Design’s Inside Electronics series focuses on the hardware, while Interact Analysis’ Off-Highway Podcast zeroes in on how OEMs adopt that hardware in the field. Together, the episodes paint a well-rounded picture of where axial flux technology and electrification are headed. They also cover what is required to integrate technology successfully.

Turning Theory into Torque for Electric & Hybrid Powertrains

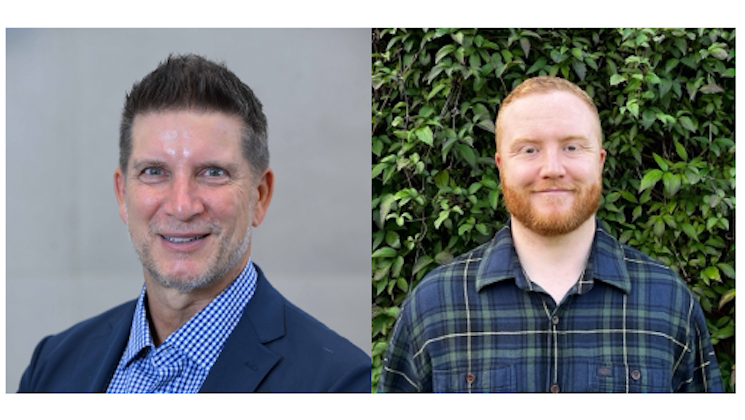

In Electronic Design’s latest episode, Technology Editor Andy Turudic interviews Turntide’s Steve Hornyak, CEO, and Adam Nixon, director, mechanical and multiphysics. They discuss the new AF430S axial flux motor and the technology in general. The trio walks through motor topologies, material choices. In addition, they cover why axial flux geometry excels at delivering high continuous torque in compact applications. This is an attractive proposition for diesel-hybrid drivetrains where space under the hood is at a premium.

Hornyak and Nixon also address supply chain pressures around rare-earth magnets, noting how careful magnet placement (or elimination) can ease cost and geopolitical risk. Beyond hybrid systems, the conversation explores:

- Tidal-energy generators

- Aerospace starter

- Ship propulsion, underscoring axial flux versatility

A concise set of show-note time stamps allows listeners to jump straight to topics like marine applications or continuous torque ratings. Learn more from the podcast “Axial-Flux Motors Gain Traction in Diesel Hybrids” from electronicdesign.com.

From Whiteboard to Worksite

Interact Analysis VP Alastair Hayfield sat down with Allison Lackenbauer, product evaluation lead for Turntide, to unpack the realities of electrifying off-highway machines. Lackenbauer urges original equipment manufacturers (OEMs) to define what “done” looks like before cutting metal because multiyear prototype cycles inevitably result in shifting requirements.

Flexibility is key: Battery chemistries evolve, duty cycles get remeasured, and regulations tighten. She recommends starting with desired outcomes—lower total cost of ownership, emissions compliance, or quieter operation—then working backward to a motor-battery-inverter package. The discussion also highlights the value of transparent data sharing between OEMs and suppliers. Check out this podcast to learn more.

Why Listening to Both Matters

Heard back-to-back, these podcasts form a continuum. Electronic Design provides the engineering foundation around electric and hybrid powertrains—magnetic flux paths, thermal management, torque density—while the podcast from Interact Analysis delivers a project-management playbook that turns that foundation into a commercially viable machine. One spells out how axial-flux motors achieve up to 30% higher power density. The other explains when and why to deploy electrification technology, and what pitfalls to avoid enroute.

Whether you’re designing the next diesel-hybrid excavator or plotting a full-electric refresh, queue up both episodes. You’ll learn actionable insights on motor selection, supply-chain strategy, and project governance—plus gain a clearer sense of how axial flux technology can accelerate the off-highway sector’s journey toward cleaner, smarter power.